|

The CRT environmental chamber for Product Temperature Mapping and Humidity testing is 5.1L x 2.3W x 2.3H metres. Achievable temperatures range from –30 to +90°C, rh 30 to 100%. For larger items and vehicles please see

specification for our environmental test chambers 1 & 2.

The environmental test chamber is automatically controlled by computer and has a dedicated

Fluke datalogger with 100 channels.

This is an affordable test chamber, which suits needs, such as high temperature/humidity testing, heat treatment or validating packaging solutions or systems.

|

Temperature and rh Control System

The entire system is controlled by a SCADA system shown here

which continuously monitors the chamber and can adjust parameters either by event or time using a strategy control option.

In the example above the strategy controller has been automatically adjusting the temperature for a packaging trial simulation of a 120-hour test period.

|

|

Datalogger

|

The Fluke datalogger shown above is capable of measuring and monitoring 100 channels. Temperature is measured using type “T” thermocouples connected to the isothermal junction box shown. Humidity is measured using a HIH rh sensor. Data can be exported directly to an Excel spreadsheet.

The datalogger is also capable of measuring other parameters such as voltage, power, pressure, flow, etc. All instrumentation is calibrated and traceable to NAMAS accreditation.

|

|

Here are some examples of testing in extreme environments for various applications

- Packaging solutions

- Elevated temperature and High humidity testing

- Product Heat treatments

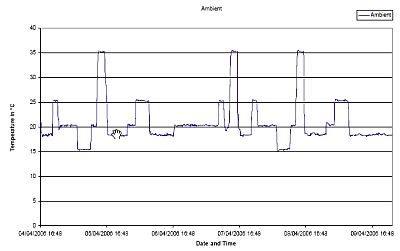

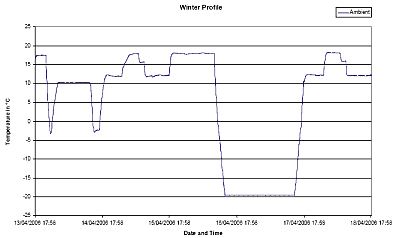

Packaging Solutions

Below are examples of ambient temperature profiles for pharmaceutical product shippers where packaging has to maintain a certain temperature when exposed to a temperature profile.

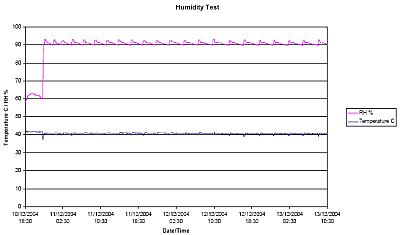

High Humidity Testing for Electrical Insulation

Resistance Breakdown

Below is an example of a high humidity test for an

electrical appliance where it was subjected to both temperature and

relative humidity.

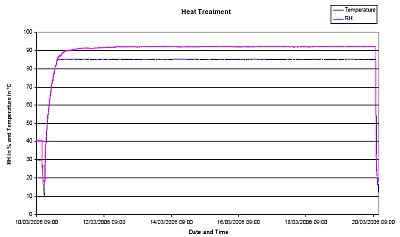

Heat Treatment

This shows a simple heat treatment test over several days with high humidity.

|